We also provide a fast labor installers force service that allows us

Challenge

Increasing Durability

Solution

Products with high resistance to thermal shock, mechanical strength, atmospheric attack and oxidation.

How do we do it?

Through the own manufacture of a combination of specific products, adapted for each type of need in each area of the kiln, which are adapted according to the requirements of use of the facilities.

1

Zones with high and fast temperature changes

Solutions that provides low reversible expansion

2

Zones with high mechanical stress and/or abrasion

We provide materials with high mechanical strength

3

Zones with aggressive atmospheres and chemical attacks

Solutions using low porosity products and paints

4

Zones with oxidizing atmospheres

Several researches drives us to achieve materials with a minimum oxidation

Challenge Installation optimization and maintenance

Solution

We design the most suitable materials for each installation based on the specific requirements of each area

How do we do it?

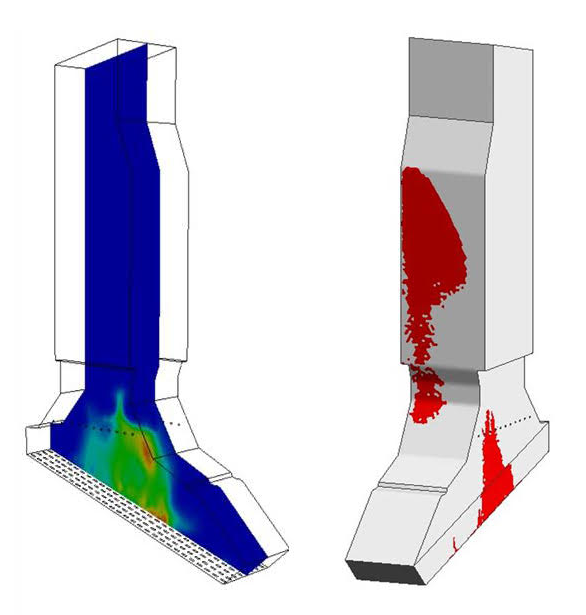

We have 5 study modules that allows us to simulate the performance of individual parts, complex structures such as incineration furnaces

We compare the original design with new proposals looking for the efficiency

SEE MODULESProposals

We have a wide range of Unshaped materials,

Shaped materials and Water Paints

UNSHAPED MATERIALS

-

Casted high quality concrete

- Hidraulic dense concrete LCC (low cement content)

- Silicon Carbide concretes

-

Gunning high quality concrete

- Hidraulic dense concrete MCC (médium cement content)

- Silicon Carbide concretes

- Precast formwork

SHAPED

MATERIALS

-

High resistance abrasion pieces

- Ceramic dense bricks

- Silicon Carbide and nitride pieces

-

Low oxidation pieces with controlled permanent dilatation

- Special Silicon Carbide shapes

WATER

PAINTS

-

Protection paintings for boiler tubes

- Air setting paintings

- Crome oxide and water paintings